Communication needs

Sample analysis

Provide solutions

Sample grinding

Check the accuracy

Experiment

After sales tracking

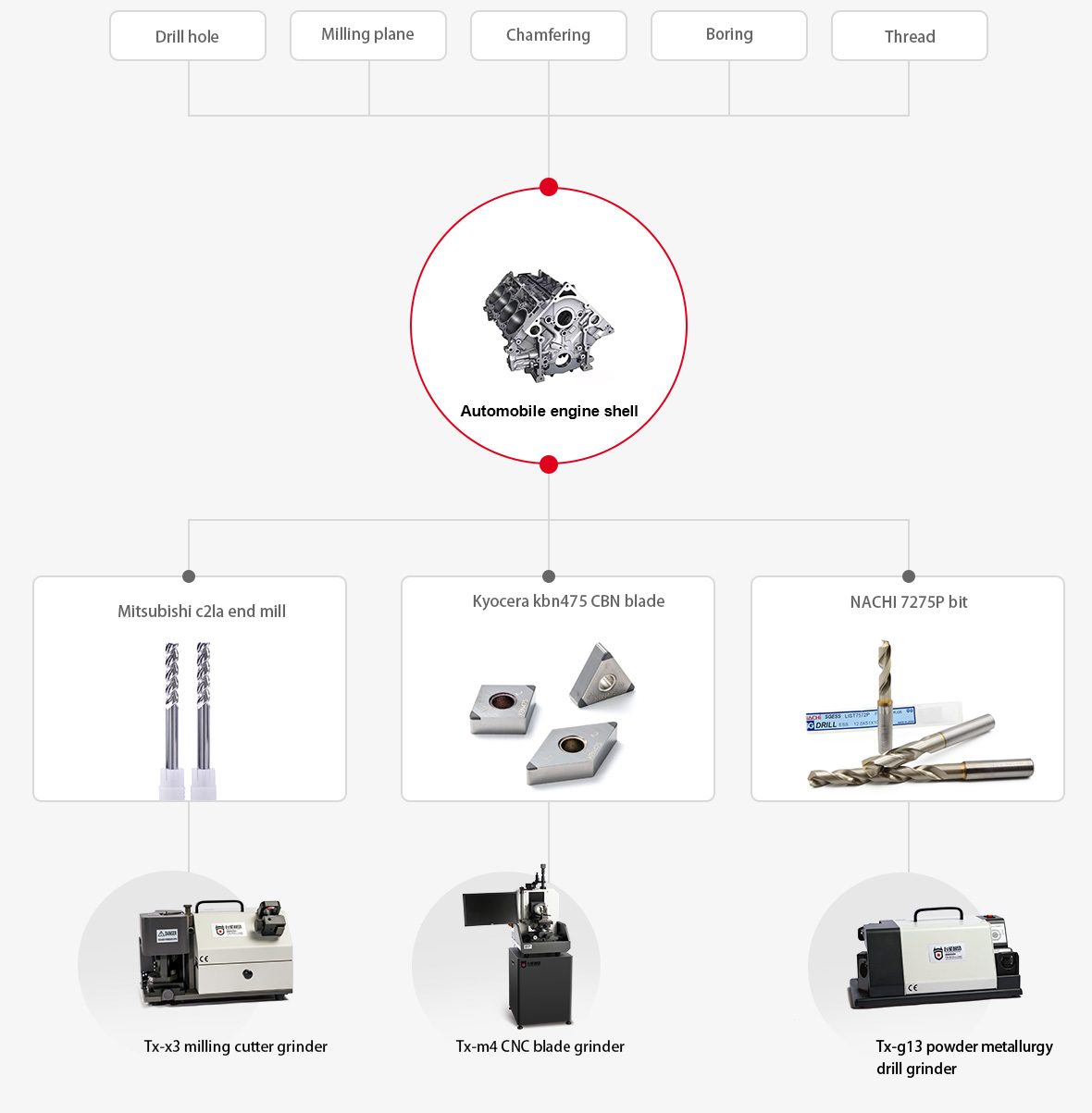

Taking the mold workshop of a company as an example, the commonly used tools are Nachi 7275p bit, Mitsubishi c2la end mill, Kyocera kbn05m CBN blade, etc;

The above cutting tools have high processing efficiency in the production process, but they are difficult to grind and have high cost.

The person in charge of the workshop immediately sent the relevant tools to our company for trial grinding and proofing after learning about the tool grinding equipment produced by Taixing Zhizao.

After receiving the tool samples, our company actively communicated with customers about technical problems, determined the needs of users, and selected matching equipment for grinding. The selection results are as follows:

Nachi 7275p drill bit --- tx-g13 powder metallurgy bit grinder;

Mitsubishi c2la end mill --- tx-x3 milling cutter grinder;

Kyocera kbn05m CBN blade --- tx-m4 CNC blade grinder;

After receiving the returned samples, the customer immediately arranged the tool test on the machine. As a result, the general service life of the new tool can reach 70% of that of the new tool, so we have reached a cooperation with TSMC. At the suggestion of our company, we set up a tool management and grinding center to collect, grind and distribute relevant tools, which effectively improves the processing efficiency and reduces the tool cost and tool inventory.

In the customer return visit one year later, we learned that the cost of cutting tools in the workshop was reduced by 40% due to the purchase of relevant equipment produced by our company, which realized the cost reduction and efficiency increase, and improved the profit margin of the enterprise.