From April 8th to 12th, 2024, the China International Machine Tool Exhibition (CCMT) will be based in Shanghai, radiating the manufacturing clusters in the Yangtze River Delta, covering China's core markets, and driving technological breakthroughs in domestic machine tools.

CCMT, along with EMO in Europe, IMTS in the United States and JIMTOF in Japan, is known as one of the world's four major international machine tool exhibitions and is the largest professional machine tool exhibition in Asia. In 2024, the exhibition will take "Digital, Interconnected, and Intelligent Manufacturing" as its theme to guide industry trends and focus on releasing the world's cutting-edge machine tool technologies.

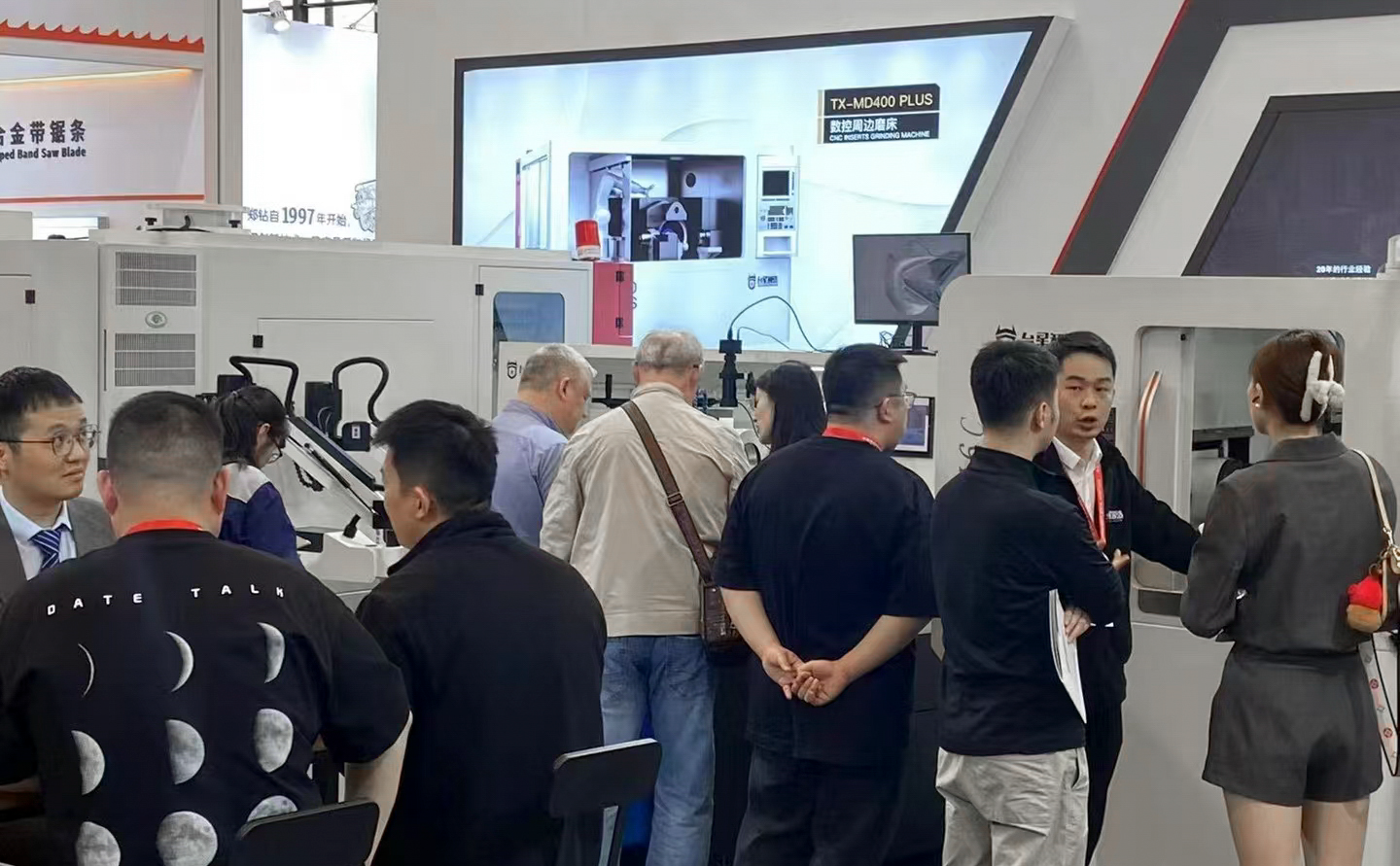

At the China International Machine Tool Exhibition (CCMT), TXMC showcased its core product lines - production-oriented tool grinders for efficient mass production and regrinding tool equipment that meets high-precision requirements. This is not only a presentation of the equipment's performance, but also an opportunity for TXMC to convey its value proposition to a wide range of manufacturing customers in the Asian region.

Relying on its long-term accumulated professional technical background and profound understanding of the pain points in the cutting tool industry, TXMC is committed to providing customers with complete solutions covering the entire life cycle of cutting tools.